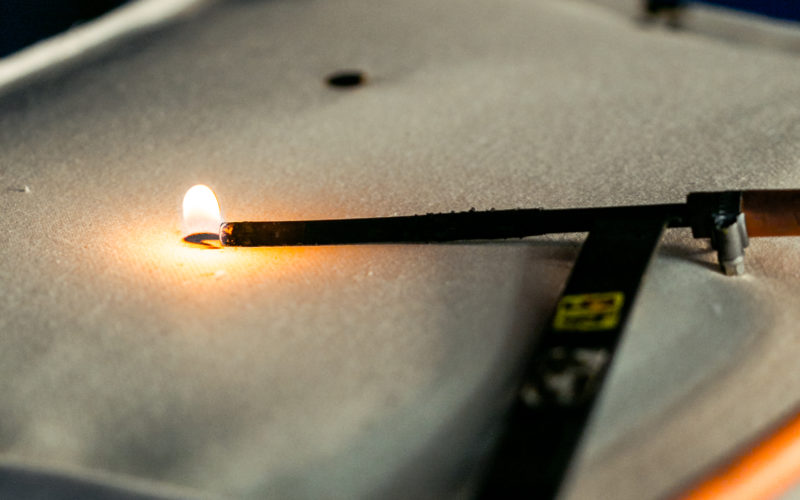

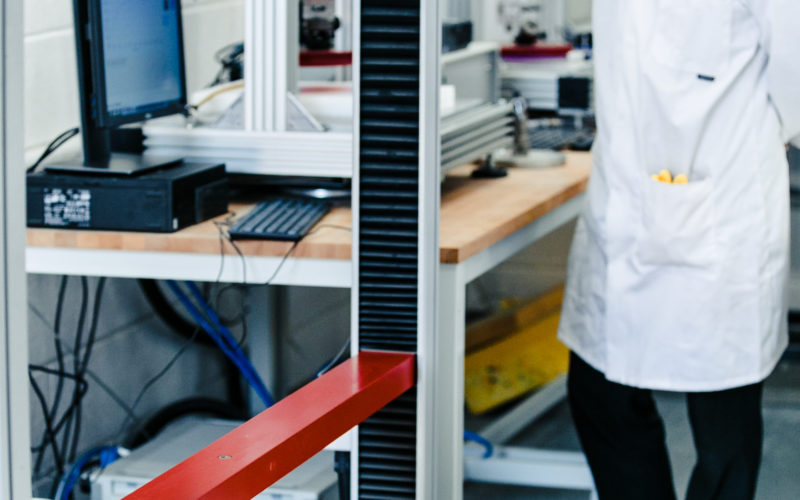

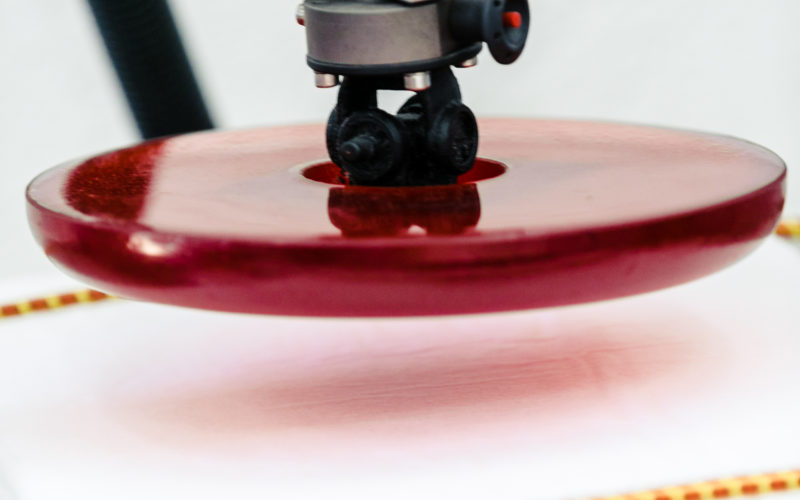

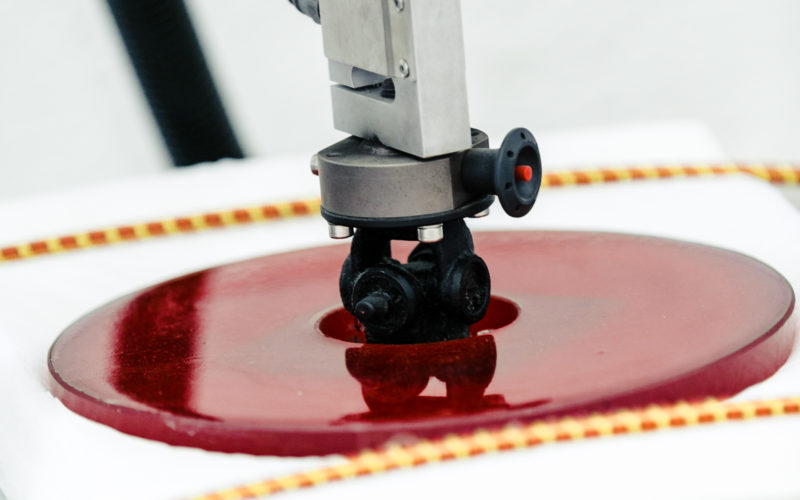

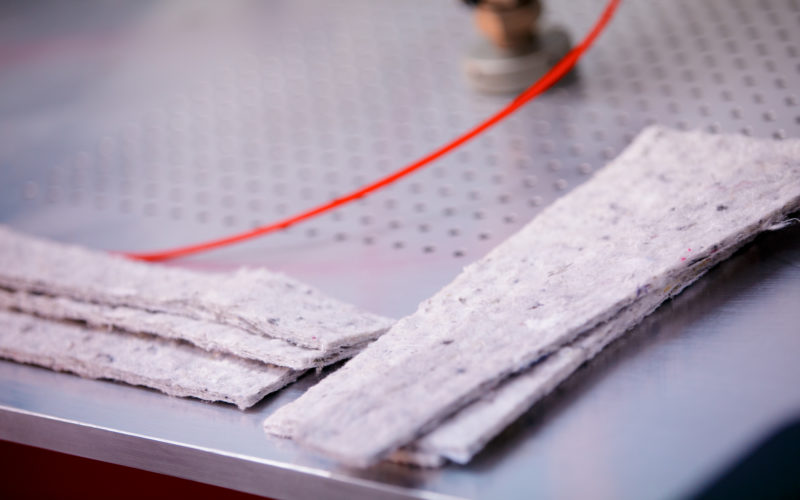

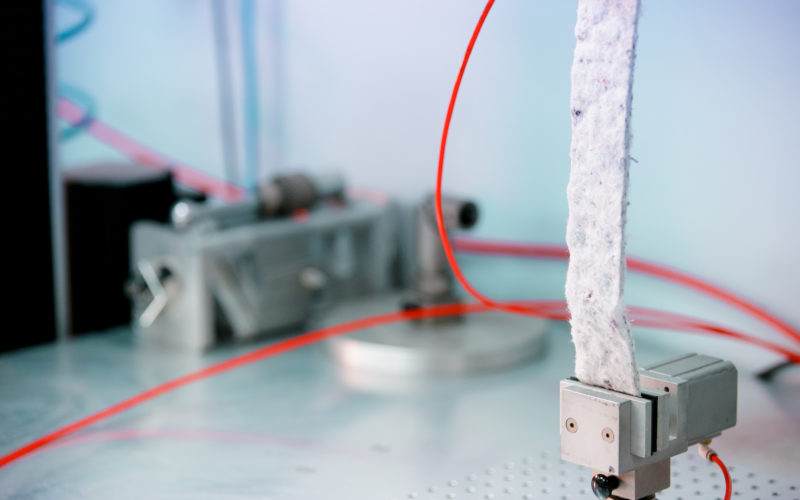

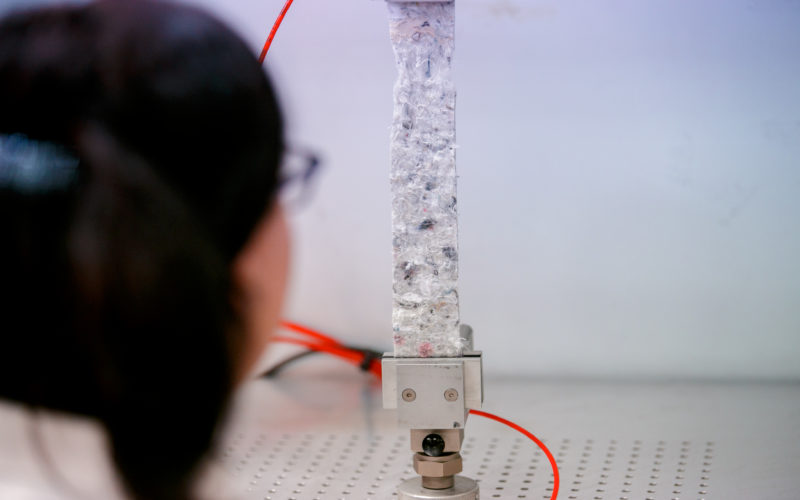

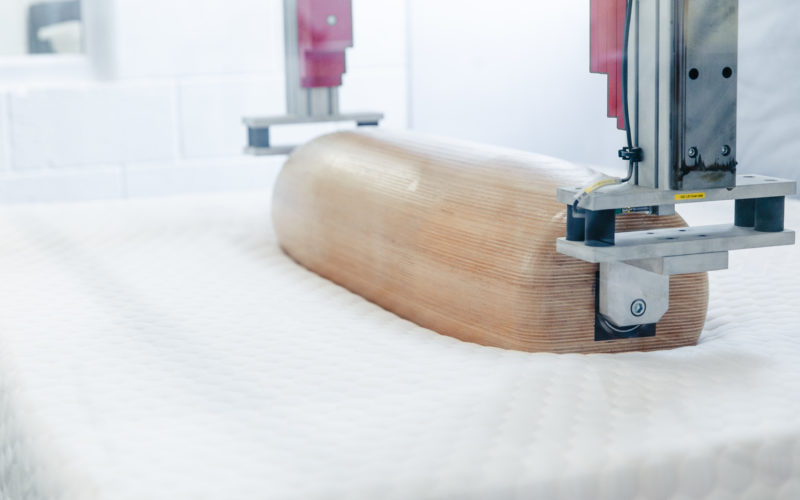

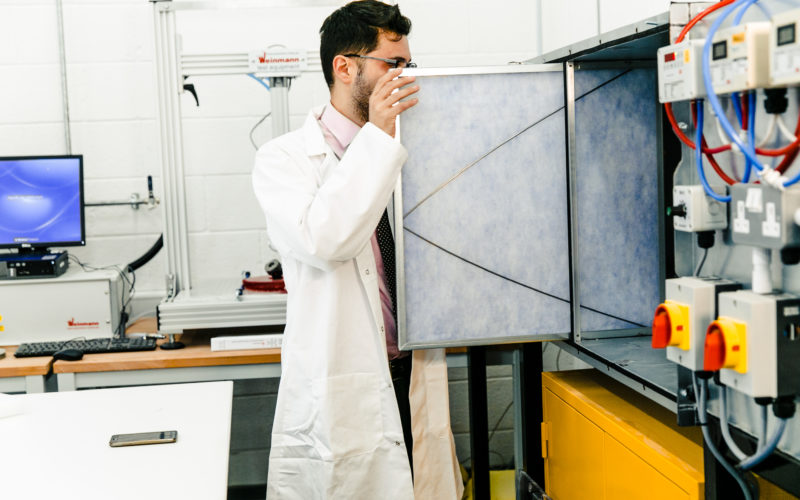

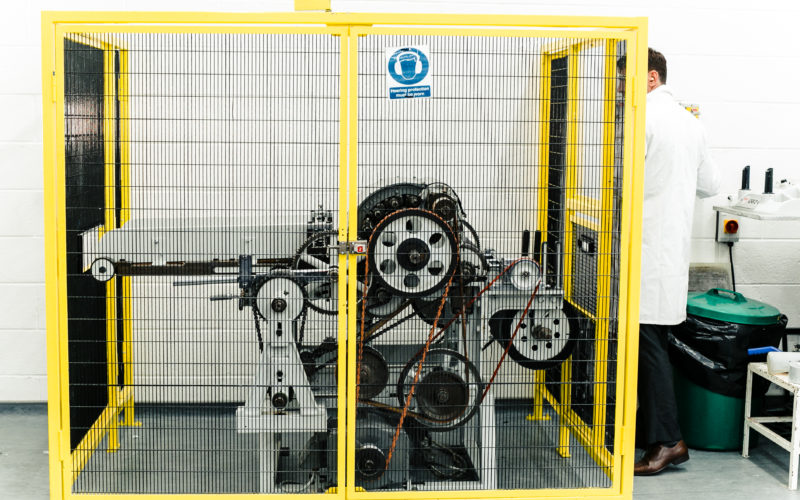

Recently, the John Cotton Group has invested over £400K to build entirely new laboratories and research and development facilities

Supporting our continued efforts to identify and develop new and innovative materials, treatments, finishes and processes to meet the ever-increasing customer demands. Our UKAS accredited commercial services, allow us to undertake a wide range of European and British standards for the bedding and upholstery and insulation markets, while the research and development team have access to an array of performance testing equipment, enabling in depth analysis of new and innovative ideas.

To view a full list of tests we are accredited for, please scroll to the bottom of this page.

Laboratory contacts:

Philip Gardner (Laboratory Manager):

pagardner@johncotton.co.uk

Andrew Ripper (UKAS Quality Manager):

aripper@johncotton.co.uk